Embrace the Future of Residential Construction

Welcome to the future of residential construction with FRAMECAD! We are firm believers that steel framing will revolutionize the way homes are built, and the time for this transformation is now. With our cutting-edge residential building system, we provide developers and home builders the tools they need to seize control and ensure future-proof construction practices.

By embracing steel framing, you not only open the door to exciting new business prospects but also position yourself as a leader in this ever-evolving industry. Stay ahead of the curve and unlock endless possibilities with FRAMECAD

How it works

FRAMECAD Structure to Revit using villty factory

Using FRAMECAD Relink you can bring streamlined design and engineering into your BIM model from FRAMECAD Structure .

- villty - import ceiling panels and wall frames from Revit and let Structure auto frame it and engineer the design.

- Ensures that the framing design is created to local standards, therefore speeding up the engineering sign-off process.

- villty allows the complete framing design to be completed in Structure (or Detailer) and then imported into Revit and merged with the architectural design.

FRAMECAD Structure to other BIM software:

By developing BIM compatibility functions, FRAMECAD Structure offers an interface to other BIM software such as ArchiCAD, Vector Works, Solid Works, Solid Edge, TEKLA and many other CAD packages.

Simply share design files between FRAMECAD Structure, Truscott and SolidWorks using IFC and ACSI (SAT) file formats.

FRAMECAD Detailer to Revit using FRAMECAD Rev link :

Using FRAMECAD Rev link allows seamless building design exchange between Revit and FRAMECAD Detailer. This maximizes efficiency ensuring you save time and money in the design, manufacturing and construction processes. FRAMECAD Detailer creates frame and truss design files efficiently for integration to the Revit building model. Changes to the design can be made in either Revit or Detailer. FRAMECAD Rev link ensures either changes are synced between the two design programs.

DISCOVER OU

COLD FORMED STEEL: WHAT IS IT?

Cold Formed Steel (also known as CFS, Light Gauge Steel & LGS), is one of the most sustainable materials used in modern buildings and is increasingly popular due to environmental factors as well as cost and efficiency . It can be seen in common household appliances & buildings all over the world. Cold formed steel's uses, composition, and properties are essential to understanding its benefits in the construction industry.

Cold-formed steel starts with the production of raw steel, combining iron ore and steel scrap with small amounts of carbon in a Basic Oxygen Furnace (BOF). The molten steel is then reduced into thinner strips of steel, and a protective coating of zinc is added through the galvanization process. The final product is called a ‘coil’ and is produced using a roll-forming machine. Using CFS in this end-to-end process makes a socially responsible building method that helps lower carbon emissions across the construction industry.

The name cold-formed steel comes from its application as it is very malleable and doesn’t require any heat to mold in its final form. Instead, the steel is bent into shape by a machine.

Taking Control

Having visibility and control as to what is happening in the supply chain is crucial for home builders. It allows them to anticipate and prevent potential issues, ensuring a smoother and more efficient workflow that leads to faster returns on investment. By maintaining control, builders can guarantee the availability and quality of materials, optimize the utilization of nonskilled labor, effectively manage costs, and maximize profits. Additionally, this level of control ensures a higher quality build, minimizing the occurrence of problems, call-backs, and warranty claims, ultimately resulting in increased customer satisfaction.

The future of construction lies in

sustainable materials

that are delivered using fast, modern methods such as a proven CFS solution available in the market.

The future of construction lies in

sustainable materials

that are delivered using fast, modern methods such as a proven CFS solution available in the market.

Companies like FRAMECAD have been providing CFS construction solutions around the world for over 25 years.

Advanced CFS construction methods such as the FRAMECAD System can result in faster build times, lower overall costs, scalable design solutions, better building performance

Enhanced Speed and Efficiency:

Our advanced steel framing process utilizes automation, allowing for rapid assembly and precise construction. With pre-engineered components and cutting-edge technology, construction timelines are significantly accelerated. This is especially advantageous for large-scale projects with tight deadlines, improving overall efficiency and reducing project duration.

Superior Strength and Durability:

Cold formed steel provides exceptional strength and durability, surpassing wood construction. It offers a robust framework that can withstand extreme weather conditions, seismic activity, and other challenges. This ensures the long-term structural integrity of the building, providing peace of mind to homeowners and developers alike.

Design Flexibility:

Steel framing allows for greater design flexibility and versatility. It can be easily customized to accommodate unique architectural features and unconventional building layouts. Architects and builders have the freedom to create innovative and aesthetically pleasing designs using steel.

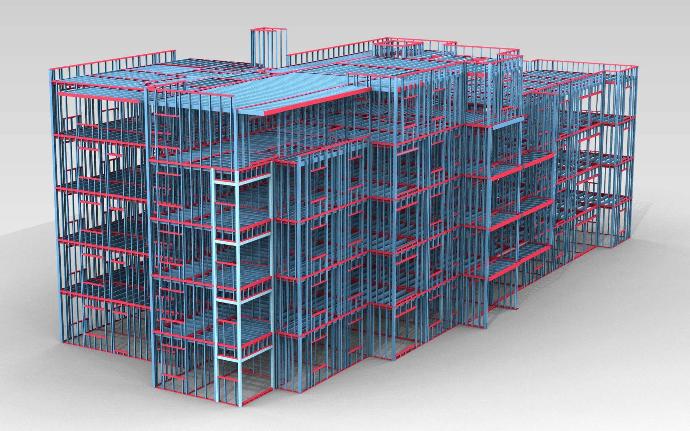

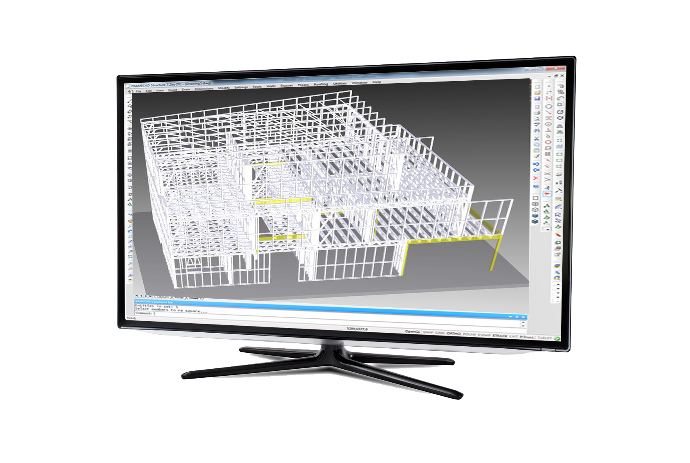

FRAMECAD Detailer is a powerful CAD-based structural detailing software that saves time and money in wall, truss and joist design for cold formed steel construction. FRAMECAD Detailer turns your structural drawings into reality, providing unbeatable accuracy in the construction process.

FRAMECAD Detailer converts design information into detailed framing plans with 3D model viewing capabilities. The structural steel detailing software enables users to quickly transfer design information from architectural designs into framing layouts, then into production. This ensures a high level of accuracy.

Using our simple plug-in (FRAMECAD Revlink) allows seamless building design exchange between Revit and FRAMECAD Detailer. This maximizes efficiency ensuring you save time and money in the design, manufacturing and construction processes.

Sustainability:

Opting for advanced steel framing aligns with sustainable construction practices. Steel is a recyclable material, making it an environmentally friendly option. By choosing steel framing, you contribute to reducing deforestation and minimizing waste. Additionally, steel is non-combustible, offering enhanced fire resistance compared to wood and enhancing the safety of the structure.

Long-Term Cost Savings:

Although the upfront cost of advanced steel framing may be slightly higher than wood construction, the long-term benefits outweigh this initial investment. The durability, low maintenance requirements, and reduced risk of issues such as warping, rot, or termite damage associated with steel framing result in significant cost savings over the lifespan of the building.